Ceramic beam SiC silicon carbide cross beam

High temperature refractory RBSiC (SiSiC) cross beams are used for the loading structure systems of tunnel kilns, shuttle kilns and many other industrial kilns.

High temperature refractory RBSiC(SiSiC)cross beams have higher strength and there are no deformations even in very high temperature. And also display long operational life. The beams are the most suitable kiln furniture for sanitary wear and electrical porcelain applications. RBSiC(SiSiC)has excellent thermal conductivity, so it is available to save energy.

High temperature refractory RBSiC(SiSiC)cross beams have higher strength and there are no deformations even in very high temperature. And also display long operational life. The beams are the most suitable kiln furniture for sanitary wear and electrical porcelain applications. RBSiC(SiSiC)has excellent thermal conductivity, so it is available to save energy.

Inquiry

|

Description

Ceramic beam SiC silicon carbide cross beam

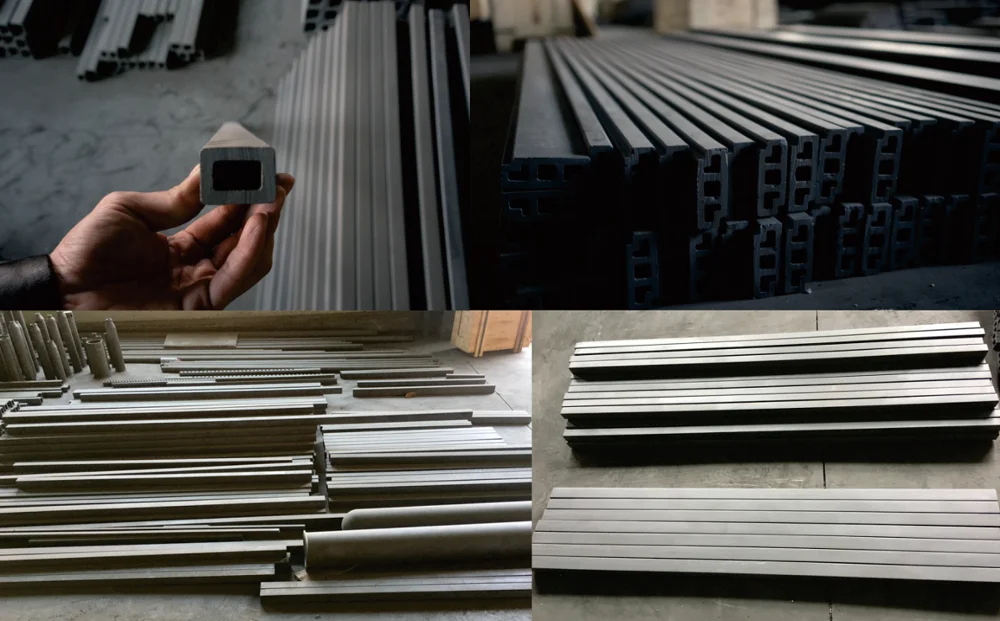

Reaction bonded silicon carbide product-RBSIC/SISIC beam, is the load-bearing frame of shuttle kiln, tunnel kiln, double roller kiln, etc. It is the ideal energy-efficient refractory kiln furniture with the features of high temperature load capacity, size stability, oxidation resistance, flex resistance, thermal shock resistance, corrosion resistance capacity and long service life(under 1380℃ degree). At present it is mainly used in electric porcelain industry, domestic ceramics, sanitary ware production industry and the actual production of various industrial furnaces. It can save energy observably without increasing the weight of kiln car.

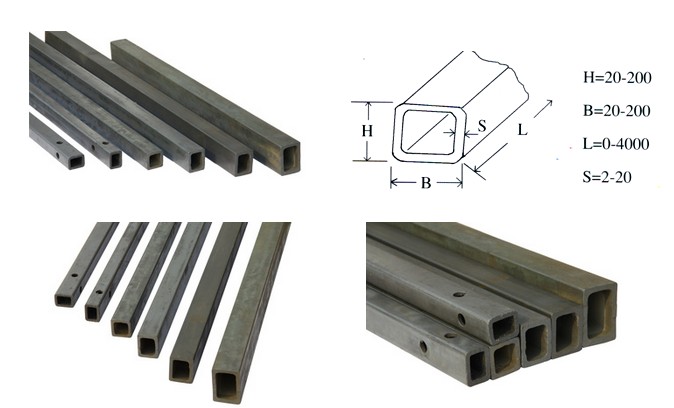

SPECIFICATION:

| Index | RSiC | NSiC | RBSiC | SiC |

| Bulk density(g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Porosity(%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Bending strength(MPa) | 80-100(20℃) | 160-180(20℃) | 250(20℃) | 500(20℃) |

| Bending strength(MPa) | 90-110(1200℃) | 170-180(1200℃) | 280(1200℃) | 550(1200℃) |

| Bending strength(MPa) | 90-120(1350℃) | 170-190(1350℃) | - | - |

| Modulus of elasticity(GPa) | 300(20℃) | 580(20℃) | 330(20℃) | 200 |

| Modulus of elasticity(GPa) | - | - | 300(1200℃) | - |

| Thermal conductivity(w.m-1.k-1) | 36.6(1200℃) | 19.6(1200℃) | 45(1200℃) | 13.5-14.5(1000℃) |

| Coefficient of thermal expansion(K-1x10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Rigidity | - | - | 13 | - |

| Max working temperature(℃) | 1620(oxid) | 1450 | 1380 | 1300 |

Contact us

ADD: Fangzi,Weifang,Shandong,China

Copyright © Silicon carbide SiC RBSIC SISIC SSIC All Rights Reserved.

Links: