Characteristics:

Max temperature tolerance 1380 degree

Excellent oxidation and corrosion resistance

High thermal conductivity and shock resistance

High mechanical strength and abrasion resistance

Relevant Recommendation:

Silicon Nitride Ceramics

Oxide bonded SiC (OSIC)

Recrystallizde SiC (Re-SiC)

Reaction Bonded SiC (SiSiC)

Inquiry

|

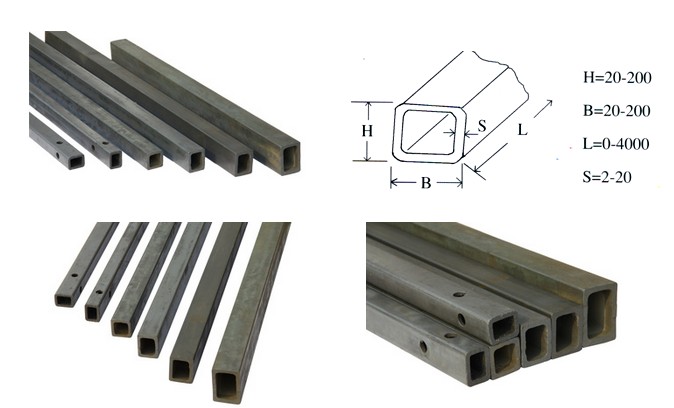

heating resistance silicon carbide ceramic beam for tunnel kiln

are mainly used for load-bearing structure frame for tunnel kiln,shuttle kiln and many other kilns.The characteristics of sic beam are high loading capacity under high temperature,no bending deformation with long service life,high thermal conductivity,save energy consumption obviously without increasing the weight of the kiln car. Sic beam is the ideal kiln furniture for sanitary ware,domestic ceramic and other industries.Recently we sunshine ceramics have developed a new style frame type energy-saving sic beam depending on customer usage,provide customers the better energy-saving solution.Our company has transformed hundreds of kiln cars for domestic and overseas customers,and has created large profits for our customers.

| Item | Unit | Data |

| Max temperature of application | ℃ | 1380 |

| Density | g/cm3 | ≥3.02 |

| Open porosity | % | <0.1 |

| Bending strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal conductivity | W/m.k | 45(1200℃) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid alkaline-proof | Excellent |

→Superior high temperature resistance,wear resistance and oxidation resistance.

→Excellent straightness,less than 1‰.

→High uniformly distributed loading capacity,more than 4997 kg.m/L.

→OEM accepted.

→Easy to install.

→Various shape accepted,Germany imported technology and materials.

→Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane).

| Size of Section(mm) | Wall Thickness(mm) | Uniformly Distributed Loading(kg.m/L) | ||

| W Side | H Side | W Side | H Side | |

| 30 | 30 | 5 | 147 | 147 |

| 30 | 40 | 5 | 235 | 190 |

| 40 | 40 | 6 | 330 | 330 |

| 50 | 50 | 6 | 567 | 567 |

| 50 | 60 | 6 | 748 | 662 |

| 50 | 70 | 8 | 1143 | 902 |

| 60 | 90 | 9 | 2120 | 1598 |

| 80 | 80 | 7 | 1869 | 1869 |

| 100 | 100 | 8 | 3416 | 3416 |

| 110 | 110 | 10 | 4997 | 4994 |

Application of silicon carbide beam: