1.High temperature tolerance

2. Thermal shock resistance

3. Corrosion resistance

4. Thermal conductivity

Inquiry

|

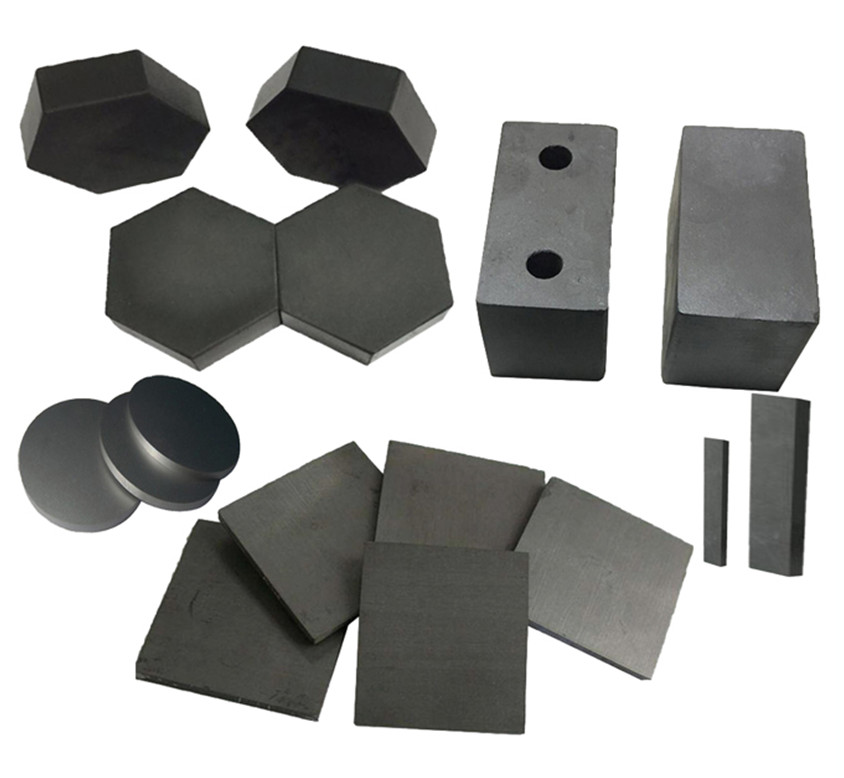

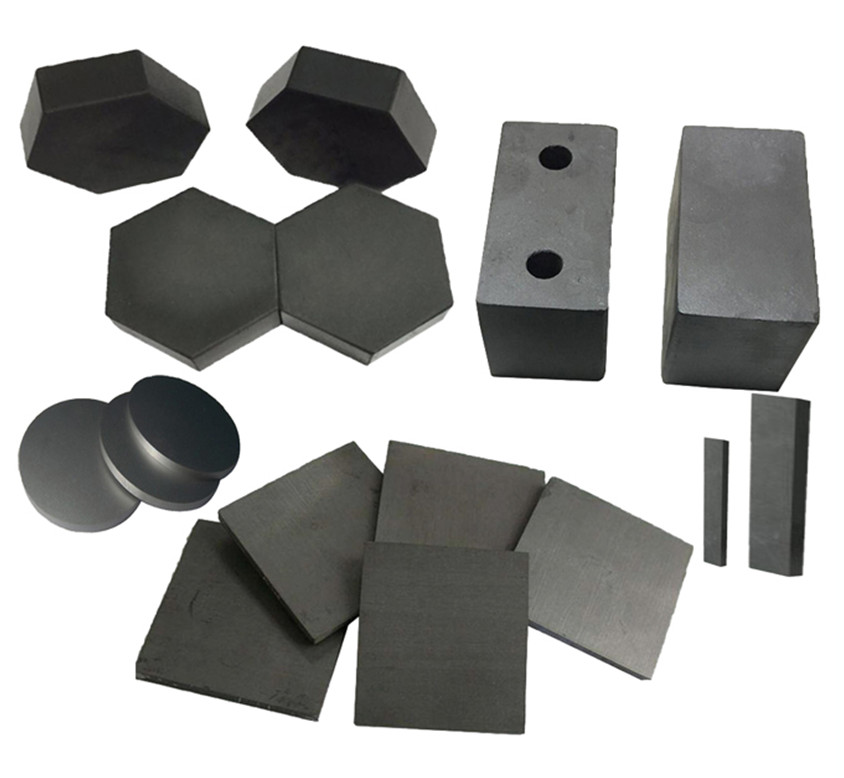

China supplier impact resistance RBSiC / SiSiC silicon carbide sic plates / tiles / sheets with high hardness, wear resistantce oxidation resistance are widely used in papermaking, chemical, electronics, pharmaceutical and other ink jet, lithium battery materials, electronic pulp nano-ceramic sanding machines.

1.Technical parameters of RBSiC / SiSiC silicon carbide sic plates / tiles / sheets :

|

ITEM |

UNIT |

DATA |

|

Temperature |

℃ |

1380 |

|

Density |

g/cm³ |

≥3.02 |

|

Open Porosity |

% |

<0.1 |

|

Moh's Scale of Hardness |

|

13 |

|

Bending Strength |

MPa |

250 (20℃) |

|

MPa |

280 (1200℃) |

|

|

Modulus of Elasticity |

GPa |

330 (20℃) |

|

GPa |

300 (1200℃) |

|

|

Thermal Conductivity |

W/m.k |

45 (1200℃) |

|

Coefficient of thermal expansion |

k-1×10-6 |

4.5 |

|

Acid Alkaline -proof |

|

Excellent |

2.Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

3. Specification of RBSiC / SiSiC silicon carbide sic plates / tiles / sheets:

Thickness available: 4mm - 45mm

Remark: Other sizes and shape are available upon requests.

4.Other RBSiC / SiSiC silicon carbide products:

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.