1.High refractoriness.

2.Good thermal conductivity.

3.Small expansion coefficient.

4.High strength.

5.Ultra thin,energy saving.

Inquiry

|

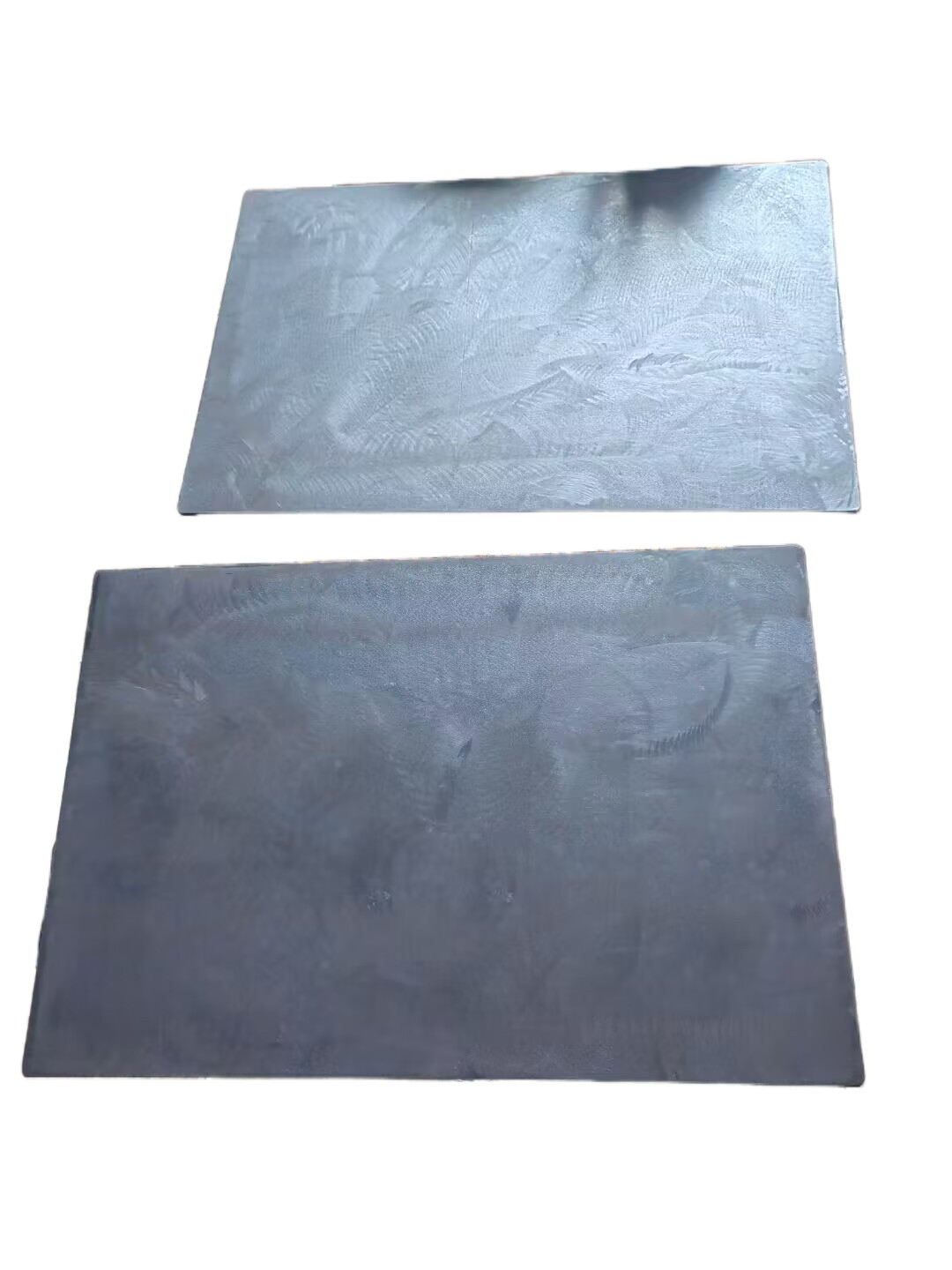

Heat resistant sic tiles / RBSiC / SiSiC silicon carbide plates / boards / sheets

is a combination of high purity silicon carbide and ultrafine powder,through vibration molding,high temperature sintering,with good high temperature thermal conductivity and bearing,applicable for all kinds of architectural ceramics,sanitary ceramics,household ceramics,porcelain refractories,powder metallurgy sintering furnace and fine ceramic kiln furniture.The reaction sintered silicon carbide shelves texture hard and brittle,with small expansion coefficient,high cold-resistance and heat-resistance,not easily deformed,good chemical stability,strong acid resistance,thin products but high bulk density,energy-saving effect is remarkable,to achieve a wear resistance,corrosion resistance,anti-fouling in one of the comprehensive performance,suitable for high wear,high corrosion environment,silicon carbide shelves is a reliable high-tech product.

RBSIC / SiSiC silicon carbide plates have good thermal conductivity and heat resistance, and are widely used in household ceramics, ceramic sanitary ware, microcrystalline glass, powder metallurgy, electronic ceramics, alumina ceramics, zirconia ceramics, high-temperature flue cover plate or partition, etc.

It can be made of square plates, round plates and various special-shaped plates. In addition, we can carry out high-temperature adhesive coating treatment on one or both sides of the ceiling plate according to user requirements.

Product features:

- Save more than 20% of energy;

- High thermal conductivity;

- Good anti-gasification performance;

- Long service life;

- Thin wall, saving space and fuel in the kiln;

- Good heat resistance performance, suitable for fast firing high-temperature kiln.

Technical parameters

|

Item |

Unit |

Data |

|

Max temperature of application |

℃ |

1380 |

|

Density |

g/cm3 |

≥3.02 |

|

Open porosity |

% |

<0.1 |

|

Bending strength |

Mpa |

250(20℃) |

|

Mpa |

280(1200℃) |

|

|

Modulus of elasticity |

Gpa |

330(20℃) |

|

Gpa |

300(1200℃) |

|

|

Thermal conductivity |

W/m.k |

45(1200℃) |

|

Coefficient of thermal expansion |

K-1×10-6 |

4.5 |

|

Rigidity |

|

13 |

|

Acid alkaline-proof |

|

Excellent |

Property:

→Superior high temperature resistance,wear resistance and oxidation resistance.

→Excellent straightness,less than 1‰.

→High uniformly distributed loading capacity,more than 4997 kg.m/L.

→OEM accepted.

→Easy to install.

→Various shape accepted,Germany imported technology and materials.

→Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane).

Packaging & Shipping

The packing type of silicon carbide product is plywood box with plastic foam inside.

Related Products

Many products can be made from siliconized silicon carbide such as:beams,rollers,burner nozzle,radiant tube,desulfurization nozzles,battes,plates,wear resistant lining materials,cooling air pipes,thermocouple protection tube,bushing,crucible,sagger,heat exchanger,sealing parts and special shaped parts,etc.

Email:[email protected] skype:masonvicky