1. Good Oxidation resistance

2. Excellent Corrosion resistance

3. High temperature tolerance

4. Perfect Bending strength

Silicon carbide cone pipe lining for pulverized coal powder conveying Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Inquiry

|

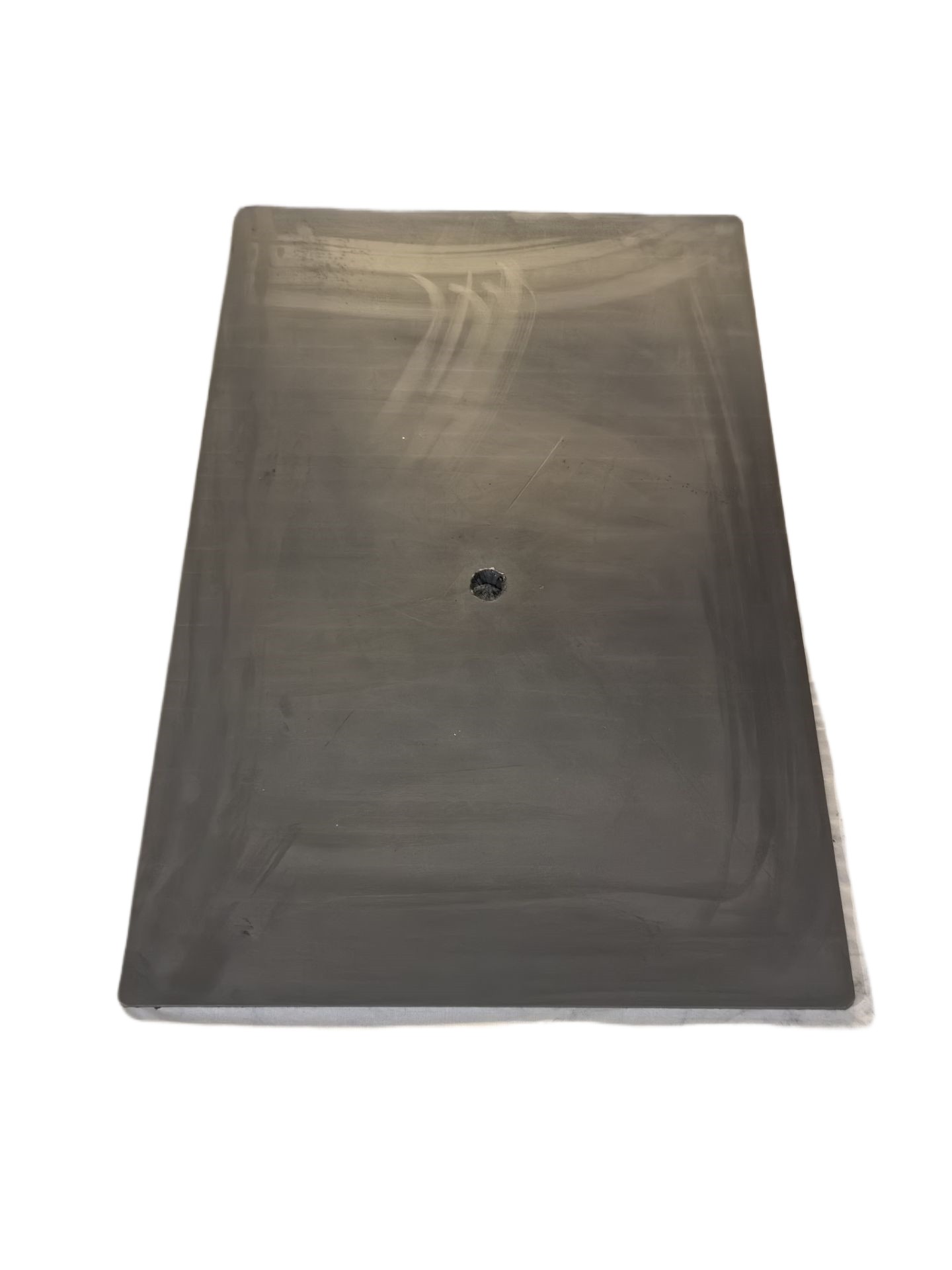

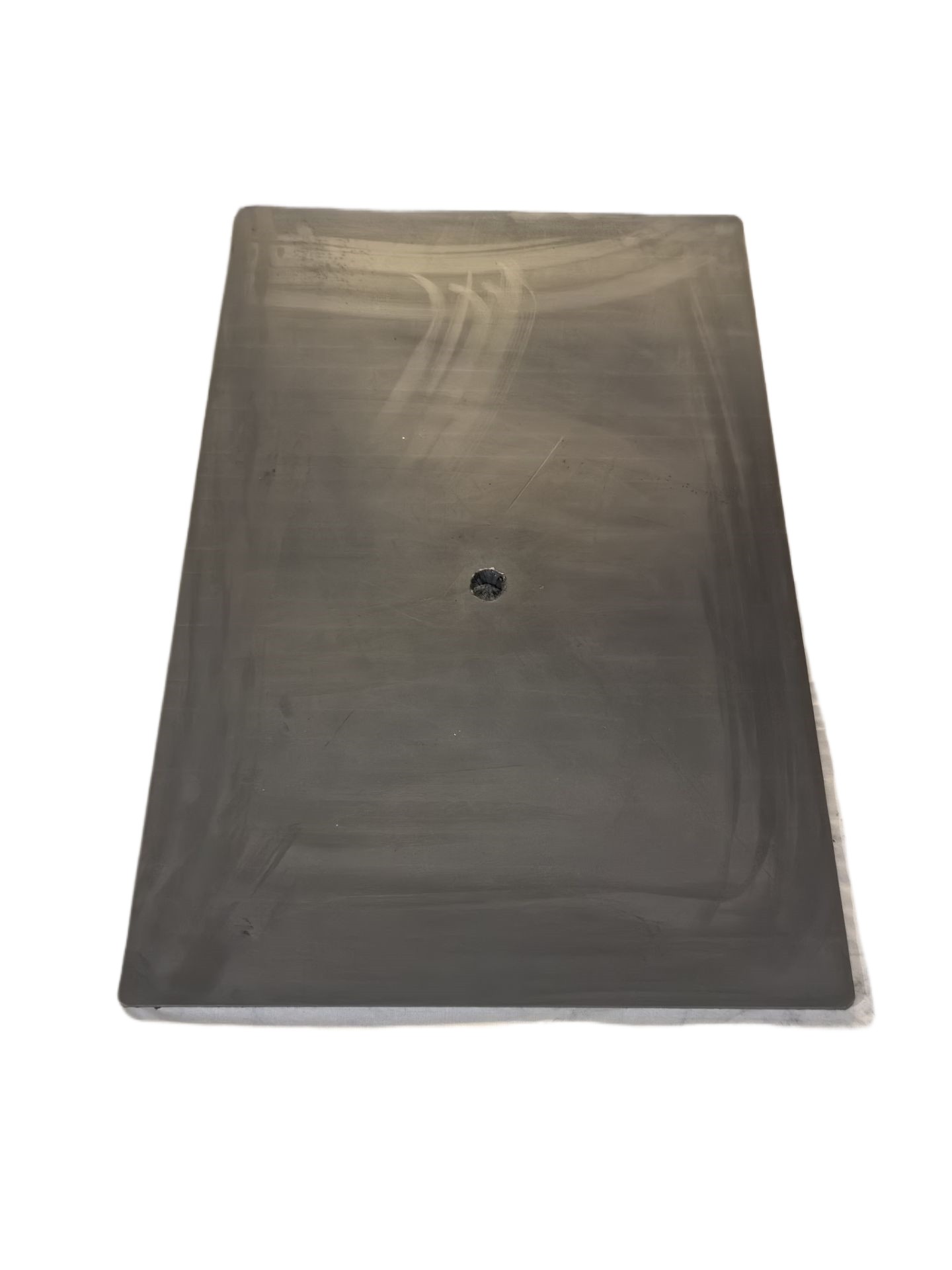

Sic Plate Ceramic Silicon Carbide Setter for Tableware Kilns

Silicon-Infiltrated Silicon Carbide (SiSiC)

It is a material with high specific rigidity and is suitable for manufacturing large complex shaped products or products with hollow structure

Silicon-Infiltrated Silicon Carbide is a silicon infiltrated composite material based on silicon carbide. Due to the infiltration of silicon, there are less pores and outgassing is suppressed. The material has a high specific rigidity with similar characteristics to Silicon Carbide and lower electrical resistance than Silicon Carbide, making it possible to eliminate static electricity from parts. Its unique manufacturing method and reactive sintering bonding facilitate the production of large, complex-shaped parts or hollow structures, and are widely used in applications such as semiconductor processing equipment.

| Item | Unit | Data |

| Max temperature of application | ºC | 1380 |

| Density | g/cm3 | ≥3.02 |

| Open porosity | % | < 0.1% |

| Bending strength | Mpa | 250(20ºC) |

| Mpa | 280(1200ºC) | |

| Modulus of elasticity | Gpa | 330(20ºC) |

| Gpa | 300(1200ºC) | |

| Thermal conductivity | W/m.k | 45(1200ºC) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| rigidity | 13 | |

| Acid alkaline-proof |

| Excellent |

Silicon carbide is generally used in the ceramic industry, but silicon carbide products can also be used in the industrial industry. The characteristics of silicon carbide refractory plate are because it is outstanding in all aspects, has good wear and tear resistance, and strong bearing capacity.

The industrial application of silicon carbide sheets is very extensive and environmentally friendly.

The role of SiC kiln furniture and the basic characteristics of kiln furniture materials:

- kiln furniture is a special refractory material, and kiln furniture is an indispensable high-temperature auxiliary material product in the ceramic industry, refractory material industry, abrasive industry, and other industries.

- According to the general requirements of ceramic products and the characteristics of kilns, kiln furniture materials must have the following basic properties: high strength, high hardness, high wear resistance, corrosion resistance, good oxidation resistance, and thermal shock resistance.

- Silicon carbide ceramics have excellent characteristics such as high mechanical strength, high-temperature resistance, strong oxidation resistance, good thermal stability, large thermal conductivity, and other excellent features.