1. Good Oxidation resistance

2. Excellent Corrosion resistance

3. High temperature tolerance

4. Perfect Bending strength

Silicon carbide cone pipe lining for pulverized coal powder conveying Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Inquiry

|

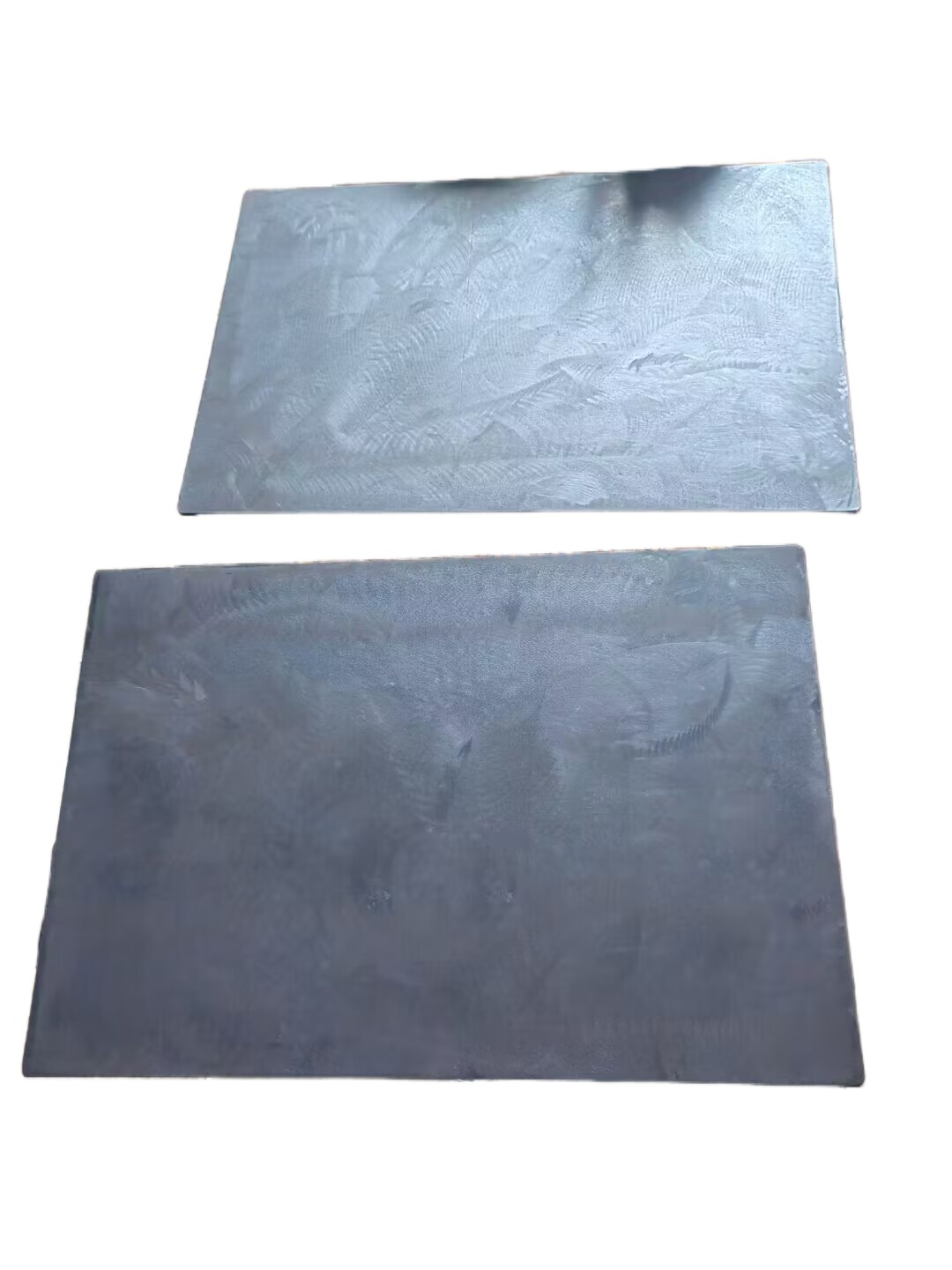

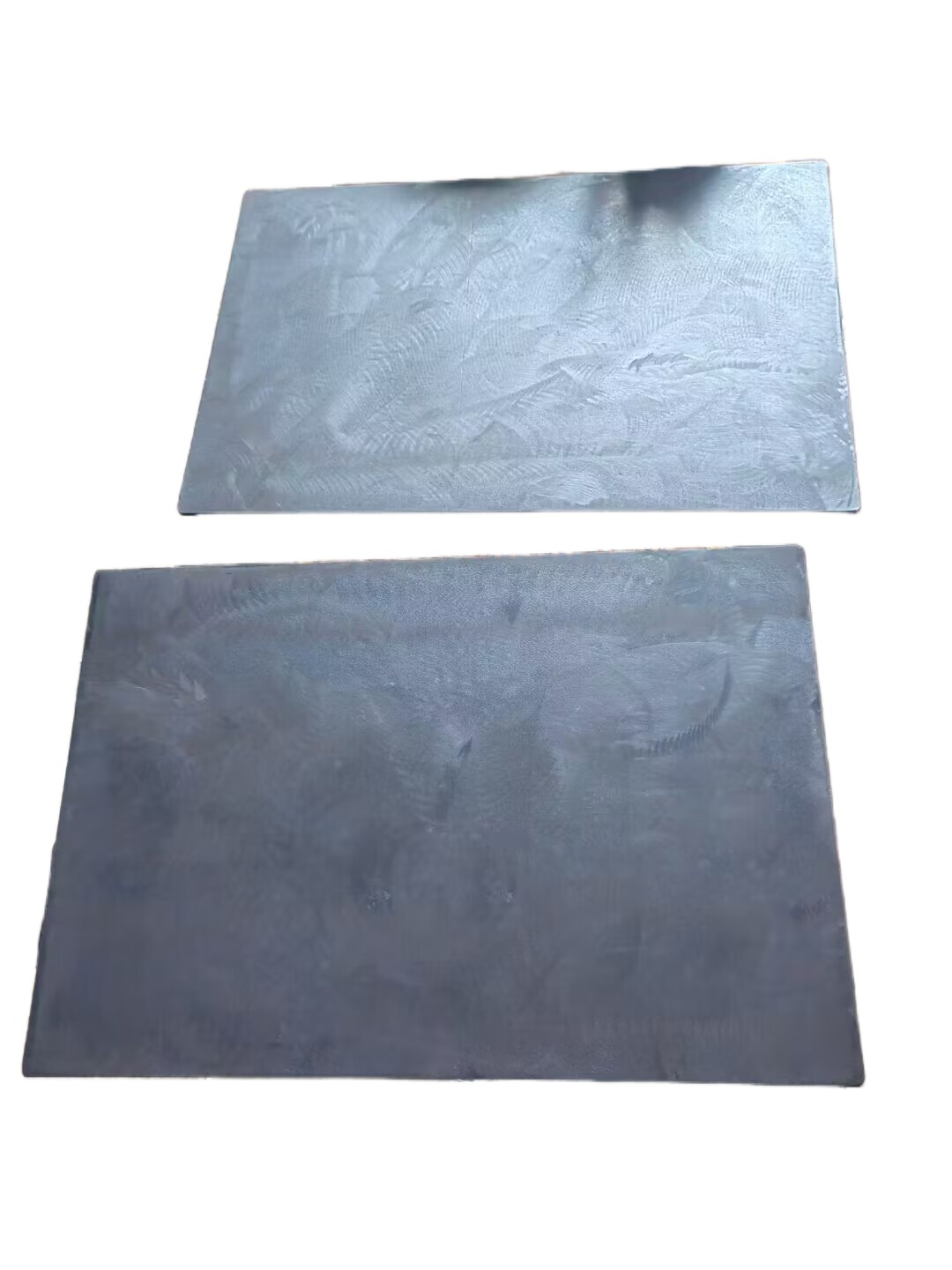

China supplier impact resistance RBSiC / SiSiC silicon carbide sic plates / tiles / sheets with high hardness, wear resistantce oxidation resistance are widely used in papermaking, chemical, electronics, pharmaceutical and other ink jet, lithium battery materials, electronic pulp nano-ceramic sanding machines.

The product has a high temperature, high strength, volume stability and good thermal conductivity, acid,

alkali and a variety of molten metal erosion ability and so on. widely used in colored aluminum tank, zinc vertical tank;

metallurgical industry, blast furnace lining, ceramic kiln shelf panels.

1.Technical parameters of RBSiC / SiSiC silicon carbide sic plates / tiles / sheets :

|

ITEM |

UNIT |

DATA |

|

Temperature |

℃ |

1380 |

|

Density |

g/cm³ |

≥3.02 |

|

Open Porosity |

% |

<0.1 |

|

Moh's Scale of Hardness |

|

13 |

|

Bending Strength |

MPa |

250 (20℃) |

|

MPa |

280 (1200℃) |

|

|

Modulus of Elasticity |

GPa |

330 (20℃) |

|

GPa |

300 (1200℃) |

|

|

Thermal Conductivity |

W/m.k |

45 (1200℃) |

|

Coefficient of thermal expansion |

k-1×10-6 |

4.5 |

|

Acid Alkaline -proof |

|

Excellent |

2.Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

3. Specification of RBSiC / SiSiC silicon carbide sic plates / tiles / sheets:

Thickness available: 4mm - 45mm

Remark: Other sizes and shape are available upon requests.

4.Other RBSiC / SiSiC silicon carbide products:

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, cooling air pipe, burner nozzles, thermocouple protecting tubes, temperature measuring parts, radiant tubes, desulfurization nozzles, crucible, batts, wear resistant lining materials, plates, seals, rings and special shaped structural parts.

The RBSIC ceramic products are widely used in high temperature ceramic kiln, steel quench furnace, large boiler, power plant desulfurization dusting equipment and high-tech military equipment. The industry involves but not limited to daily-use ceramics, sanitary ceramics, porcelain insulator, crystallite glass, metallurgy, magnetic materials, electric power, chemical industry, steel, petroleum, machinery, military industry, etc.

Batts are used as the basic support element in most kilns and furnace structures, forming a flat, rigid surface which carries the ware during firing, sintering or heat treatment.

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, cooling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

Email:masonvicky skype:masonvicky