Characteristics:

Max temperature tolerance 1380 degree

Excellent oxidation and corrosion resistance

High thermal conductivity and shock resistance

High mechanical strength and abrasion resistance

Relevant Recommendation:

Silicon Nitride Ceramics

Oxide bonded SiC (OSIC)

Recrystallizde SiC (Re-SiC)

Reaction Bonded SiC (SiSiC)

Inquiry

|

Technical parameters of reaction bonded silicon carbide RBSIC :

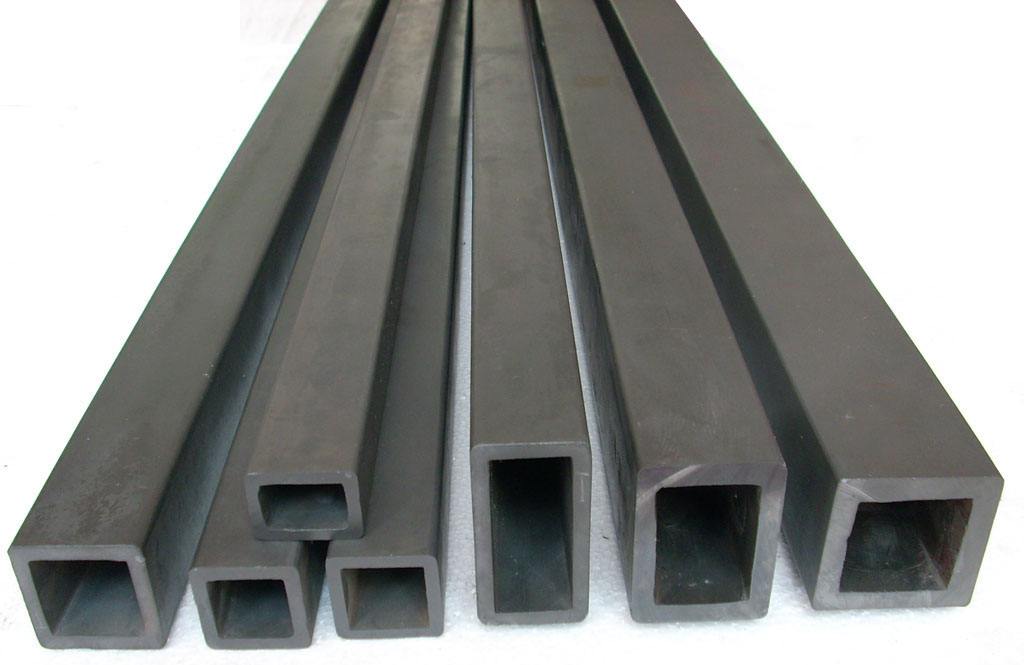

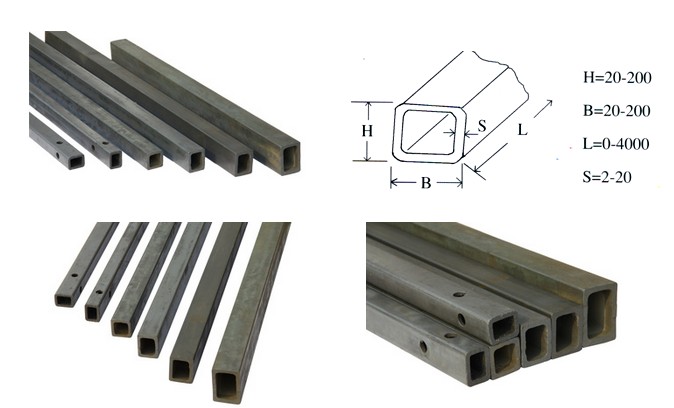

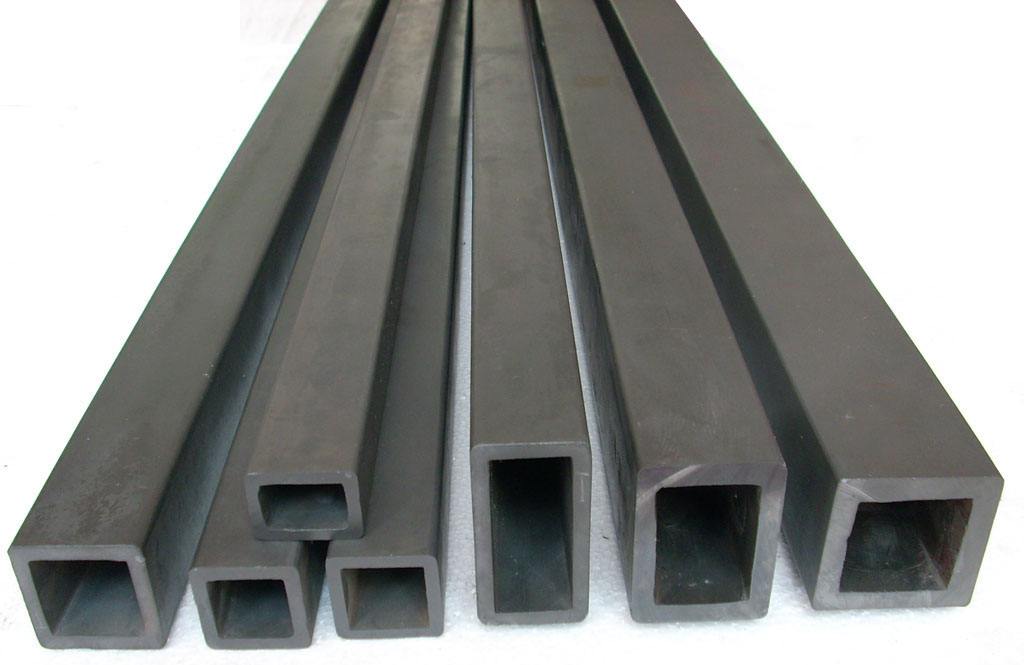

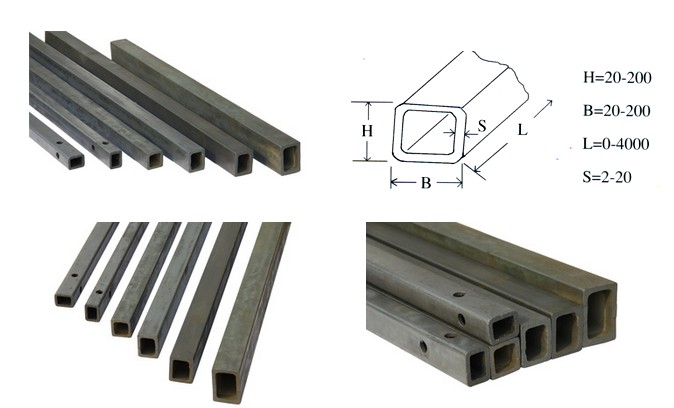

RBSIC silicon carbide square tube / sic beam for kiln furniture are used for the loading structure systems of tunnel kilns, shuttle kilns and many other industrial kilns. RBSIC ceramic cross beams have higher strength and there are no deformations even at high emperatures, and also the beams display ver long service life. They are the most suitable kiln furnature for sanitarywear and electrical porcelain applications.Besides, RBSIC beams have excellent thermal conductivity, so it is available to save energy with less weight of the kiln car.

Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

The reaction bonded silicion carbide ceramic ( RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive, coarse particles, classification, concentration, dehydration and other operations. Due to the above properties, the reaction bonded silicon carbide RBSIC wear resistant ceramic tubes can effectively protect the part from high wear so as to prolong the service life of the equipment.

|

Bearing Capacity of Beams |

||||||

|

Size of Section (mm) |

|

Concentrated Loading (kg.m/L) |

Uniformly Distributed Loading(kg.m/L) |

|||

|

B Side |

H Side |

B Side |

H Side |

B Side |

H Side |

|

|

30 |

30 |

5 |

74 |

74 |

147 |

147 |

|

30 |

40 |

5 |

117 |

95 |

235 |

190 |

|

40 |

40 |

5 |

149 |

149 |

298 |

298 |

|

50 |

50 |

6 |

283 |

283 |

567 |

567 |

|

50 |

60 |

6 |

374 |

331 |

748 |

662 |

|

50 |

70 |

6 |

473 |

379 |

946 |

757 |

|

60 |

60 |

7 |

481 |

481 |

962 |

962 |

|

80 |

80 |

7 |

935 |

935 |

1869 |

1869 |

|

100 |

100 |

8 |

1708 |

1708 |

3416 |

3416 |

|

110 |

110 |

10 |

2498 |

2498 |

4997 |

4997 |

The Bending Strength of RBSIC(SiSiC) Beams is 250MP, safety coefficient is 5.

Concentrated Loading =the Value in the Table Accordingly x 1/L,

Uniformly Distributed Loading = the Value in the Table Accordingly x 1/L。

We are offering any other kinds of kiln furniture and engineer ceramics ware on request.