1. Good Oxidation resistance

2. Excellent Corrosion resistance

3. High temperature tolerance

4. Perfect Bending strength

Silicon carbide cone pipe lining for pulverized coal powder conveying Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Inquiry

|

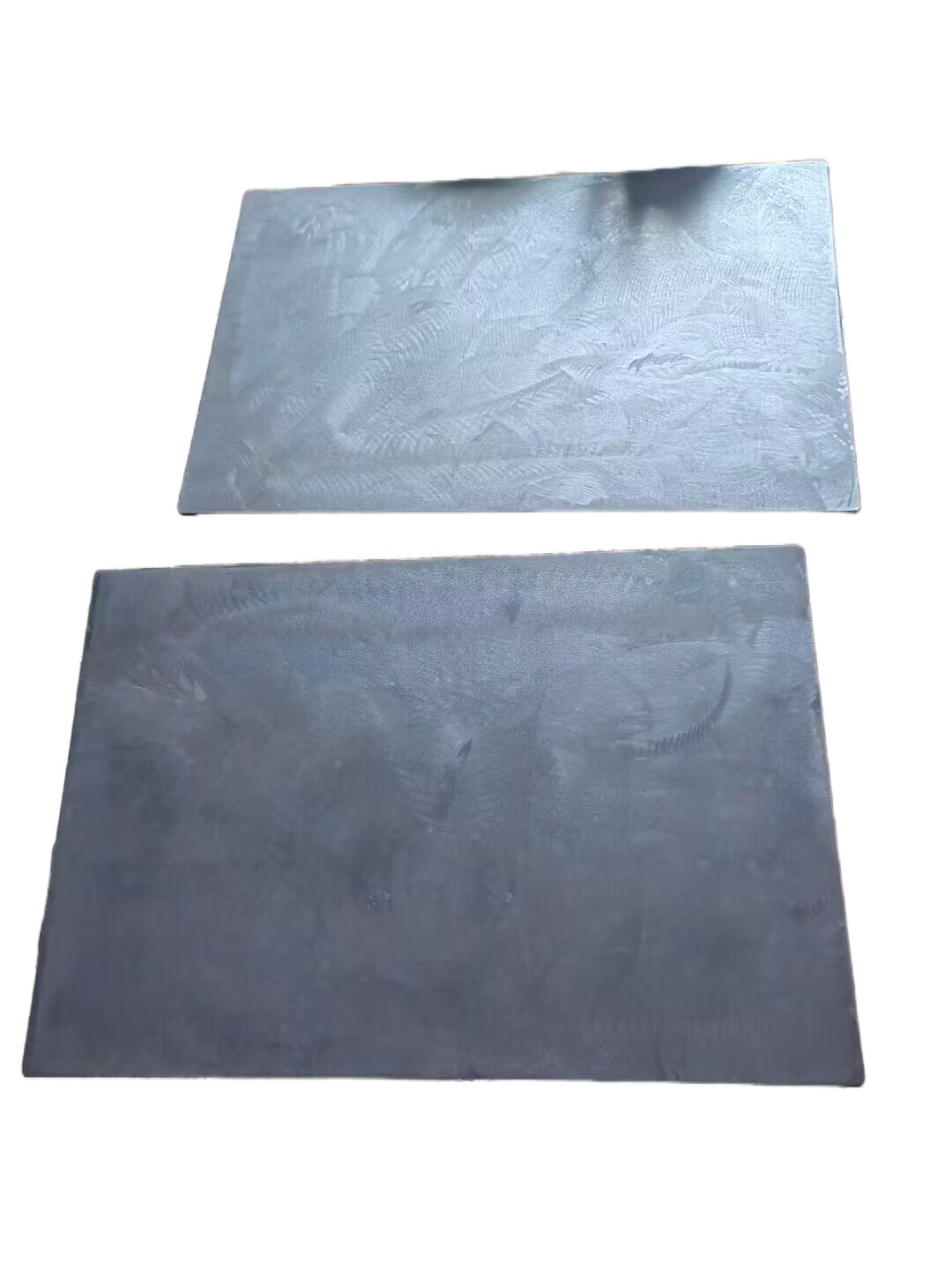

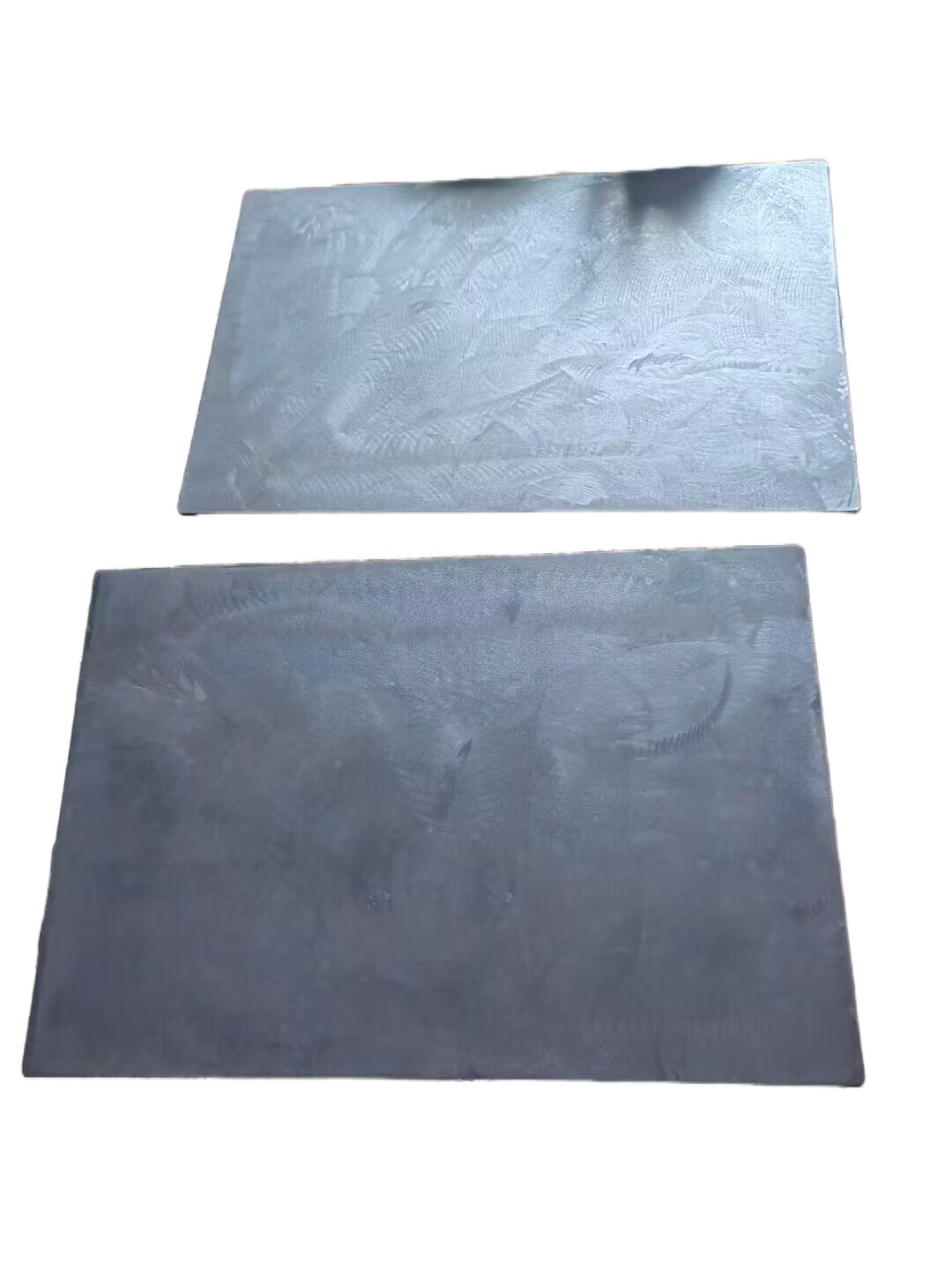

Silicon Carbide Pusher Plate - Brief Introduction

Silicon carbide pusher plates are critical components used in pusher kilns, typically manufactured from high-purity silicon carbide material.

Key Features:

-

High temperature resistance: Can operate long-term at 1300-1600°C

-

High load capacity: Can be stacked in multiple layers, increasing loading capacity

-

Thermal shock resistance: Suitable for rapid heating/cooling processes

-

Dimensional stability: No deformation at high temperatures, ensuring smooth operation

-

Long service life: 3-10 times longer lifespan than traditional alumina pusher plates

Main Applications:

-

Sintering of lithium battery cathode and anode materials

-

Firing of special ceramics

-

Heat treatment of electronic materials

-

Ceramic product manufacturing

Specification Range:

-

Length: 500-2500mm

-

Width: 300-800mm

-

Thickness: 20-60mm

With its excellent performance and long service life, silicon carbide pusher plates have become the ideal choice for modern high-temperature industrial kilns.